These devices are used for Grenoble INP - Pagora, UGA teaching activity and as pilots regarding LGP2 research work.

They can be accessed for industrial trials.

Fourdrinier paper machine

Operating conditions are fare from actual paper machine ones but anyhow, making trials can be a good step between laboratory and production.

Examples: testing a new fiber composition, working on retention agent or additives... The paper machine can be adapted to use new equipements.

Production capacity : 100 kg/hr

Production capacity : 100 kg/hr

Head box width : 1 m

Basis weight from 20 to 400 g/m²

Production speed: from 5 to 30(50) m/mn

ALLIMAND type head box and distributor

Vacuum boxes and vacuum cylinder

Sampling and injection possible all along the wet section

2 press sections with hard and soft roller

Press on {A side + A side} OR {A side + B side}

Drying section with 5 steam cylinders (3Bar max) disposed on 3 sections (1+2, 3+4, 5)

Drying on A side (section 1 & 2), drying on B side (section 3)

Cylinders 1 to 4 covered with Teflon film

Pope type rolling section

7 DC drives control

Centralized control loops and measuremen (ABB system).

Examples: testing a new fiber composition, working on retention agent or additives... The paper machine can be adapted to use new equipements.

Production capacity : 100 kg/hr

Production capacity : 100 kg/hrHead box width : 1 m

Basis weight from 20 to 400 g/m²

Production speed: from 5 to 30(50) m/mn

ALLIMAND type head box and distributor

Vacuum boxes and vacuum cylinder

Sampling and injection possible all along the wet section

2 press sections with hard and soft roller

Press on {A side + A side} OR {A side + B side}

Drying section with 5 steam cylinders (3Bar max) disposed on 3 sections (1+2, 3+4, 5)

Drying on A side (section 1 & 2), drying on B side (section 3)

Cylinders 1 to 4 covered with Teflon film

Pope type rolling section

7 DC drives control

Centralized control loops and measuremen (ABB system).

Pulp preparation

5 m³ low consistency pulper (3 % to 5 %).

Double Disk 16 inch refiner connected to two 10 m³ tanks (hydracyle mode or monocycle mode).

10 m³ paper machine main tank (2 % consistency typ.).

Cylinder Mould Paper Machine

Production capacity : 6 kg/hr.

Head box width : 0.36 m.

Basis weight from 40 to 100 g/m² (70 g/m² typ.).

Max production speed : about 10 m/mn (5 m/mn typ.).

Gravitational draining only on the round metallic wire.

“Minimal” °SR : about 30.

Watermark and pre-cutting on wire possible.

Cotton fabric based felt, vacuum boxes.

1 press section : hard and soft cylinder.

Electrical dryer section : two 12 kW IR radian cylinder (Sopara).

3 AC drive control (wet section+press, dryer, pope type rolling section).

Centralized control loops and measurement (Eurotherm system).

2 m³ Pulper / tank.

Head box width : 0.36 m.

Basis weight from 40 to 100 g/m² (70 g/m² typ.).

Max production speed : about 10 m/mn (5 m/mn typ.).

Gravitational draining only on the round metallic wire.

“Minimal” °SR : about 30.

Watermark and pre-cutting on wire possible.

Cotton fabric based felt, vacuum boxes.

1 press section : hard and soft cylinder.

Electrical dryer section : two 12 kW IR radian cylinder (Sopara).

3 AC drive control (wet section+press, dryer, pope type rolling section).

Centralized control loops and measurement (Eurotherm system).

2 m³ Pulper / tank.

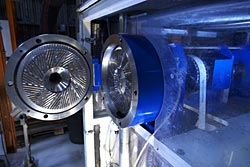

Refining pilot

The study of the characteristics development of a certain type of fiber can be easily performed on the pilot with a low amount of pulp and in replicable conditions to those industrial systems. Its small size also allows to validate low-cost new geometries and new discs materials.

300 mm (12 inch) Single Disk refiner (AC drive + motor 55 kW)

Low consistency (2 % to 5 %) in hydracycle mode (3,5 % typ.)

500 liters pulper (type 16 kg of pulp)

PC based measurement : pressure, flow, power, force, temperature, disks gap

Different disks type : cutting or fibrillating effect, HW, SW (3-3-4, 2-2-4 code, -5 / +5, +10 / +15 angle …)

300 mm (12 inch) Single Disk refiner (AC drive + motor 55 kW)

Low consistency (2 % to 5 %) in hydracycle mode (3,5 % typ.)

500 liters pulper (type 16 kg of pulp)

PC based measurement : pressure, flow, power, force, temperature, disks gap

Different disks type : cutting or fibrillating effect, HW, SW (3-3-4, 2-2-4 code, -5 / +5, +10 / +15 angle …)

Typical trial

- 5 samples with °SR measurement.

- Extended possibility : WRV, Morfi, handsheets & tests.

Hollander beater

660 mm width and diameter

660 mm width and diameterLong fibers cutting (cotton, fabric…)

Washing drum

1 m³ capacity, 3.5 % consistency typ.